Then it is heated to produce molten liquid. First purified polycrystalline silicon is created from the sand. It is the base or substrate for entire chip. It is more suitable for manufacturing IC. Silicon is preferred due to its characteristics. The wafer is a round slice of semiconductor material such as silicon. Hundreds of integrated circuits can be made on a single thin silicon. The electrically active regions are created due to this layering in and on the surface of wafer. The steps includes 8-20 patterned layers created into the substrate to form the complete integrated circuit. The manufacturing of Integrated Circuits (IC) consists of following steps. IC can function as amplifier, oscillator, timer, counter, computer memory etc. IC is the principal component in all electronic devices. high processing speed, easy replacement, etc. It has so many advantages such as extremely small size, small weight, low cost, low power consumption. and their interconnections are done at same time. In IC chips, the fabrication of circuit elements such as transistors, diodes, capacitors etc. The steps to fabricate IC chips is similar to the steps required to fabricate transistors, diodes etc. It require microscope to see connections between components. All circuit components and interconnections are formed on single thin wafer (substrate) is called monolithic IC. The active and passive components such as resistors, diodes, transistors etc and external connections are usually fabricated in on extremely tiny single chip of silicon. It is a semiconductor wafer in which millions of components are fabricated.

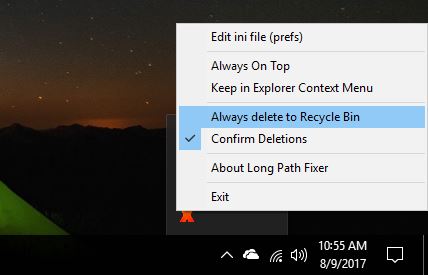

#LONG PATH TOOL CHIP HOW TO#

How to manufacture an IC? Integrated Circuit (IC)Īn Integrated Circuit (IC) is also called as chip or microchip.

0 kommentar(er)

0 kommentar(er)